Getting Started: What Every Australian Homeowner Should Know

Thin stone veneer installation is revolutionizing home renovations across Australia. It offers the classic elegance of stone without the excessive weight and expense of traditional masonry. This guide will walk you through the essential first steps of your thin stone veneer project, setting you up for a flawless installation.

Understanding Thin Stone Veneer

What exactly is thin stone veneer? Think of it as a slim, adaptable material that perfectly mimics the appearance and texture of natural stone. Picture a slice of genuine stone, precisely cut to a fraction of its original thickness. This preserves the stone’s inherent beauty and texture while dramatically reducing its weight and installation challenges. This makes it a versatile choice for a variety of applications, from accentuating feature walls and fireplaces to enhancing exterior cladding.

Choosing the Right Stone

When selecting materials for your thin stone veneer project, explore the diverse range of stone types available. Each offers a unique aesthetic. Companies like Stone Island provide excellent design inspiration. You'll discover both manufactured and natural thin stone veneer options in Australia. Manufactured stone veneer delivers remarkable consistency in color and texture, ensuring predictable results for large-scale projects. Natural thin stone veneer, conversely, showcases the distinctive variations found in real stone, injecting character and a touch of the Australian outback into your design. The increasing demand for locally sourced materials has fueled the popularity of natural veneer. In fact, the Australian market is experiencing a revival in the use of these materials, with stone veneer leading the charge. Stunning stone veneers, handcrafted by skilled Australian artisans, now grace impressive facades and interiors, reflecting Australia’s unique geological splendor. Learn more about this trend.

DIY or Professional Installation?

Honestly assess your project’s scale and your DIY abilities. Smaller projects, such as a feature wall, might be perfect for an enthusiastic DIYer. However, larger, more intricate installations, particularly exterior cladding, often demand professional expertise. Consider factors like the installation height, the surface complexity, and your comfort level using specialized tools and materials. This honest evaluation will help you avoid costly errors and ensure a durable, beautiful outcome. Thorough planning is the cornerstone of any successful installation. The next crucial step is understanding the necessary preparations.

Smart Money Decisions: Real Cost Breakdown Analysis

Embarking on a thin stone veneer project in Australia? Understanding the financial implications is paramount to your renovation's success. This guide breaks down the real costs, empowering you to budget effectively and sidestep unforeseen expenses.

Material Costs

The price of thin stone veneer varies based on the type of stone, its origin, and the supplier. Manufactured stone veneer is typically more budget-friendly than natural stone, thanks to its controlled production process and readily available materials. However, the unique aesthetic of natural stone can justify its higher cost for some homeowners.

Installation Costs

Labor costs hinge on project complexity and local contractor rates. Intricate designs and challenging installations demand more skilled labor, hence higher costs. Hiring a qualified professional for complex projects, especially exterior cladding or intricate designs, can significantly impact your budget.

Hidden Costs

Don't overlook the "hidden" costs! These often include:

- Surface preparation: Cleaning, leveling, and preparing the installation surface.

- Structural modifications: Any necessary changes to your existing structure to support the veneer's weight.

- Specialized tools: Purchasing or renting tools specific to the installation.

- Consultations: Fees for professional design, material selection, or installation advice.

These seemingly minor expenses can quickly accumulate, so factor them in from the outset.

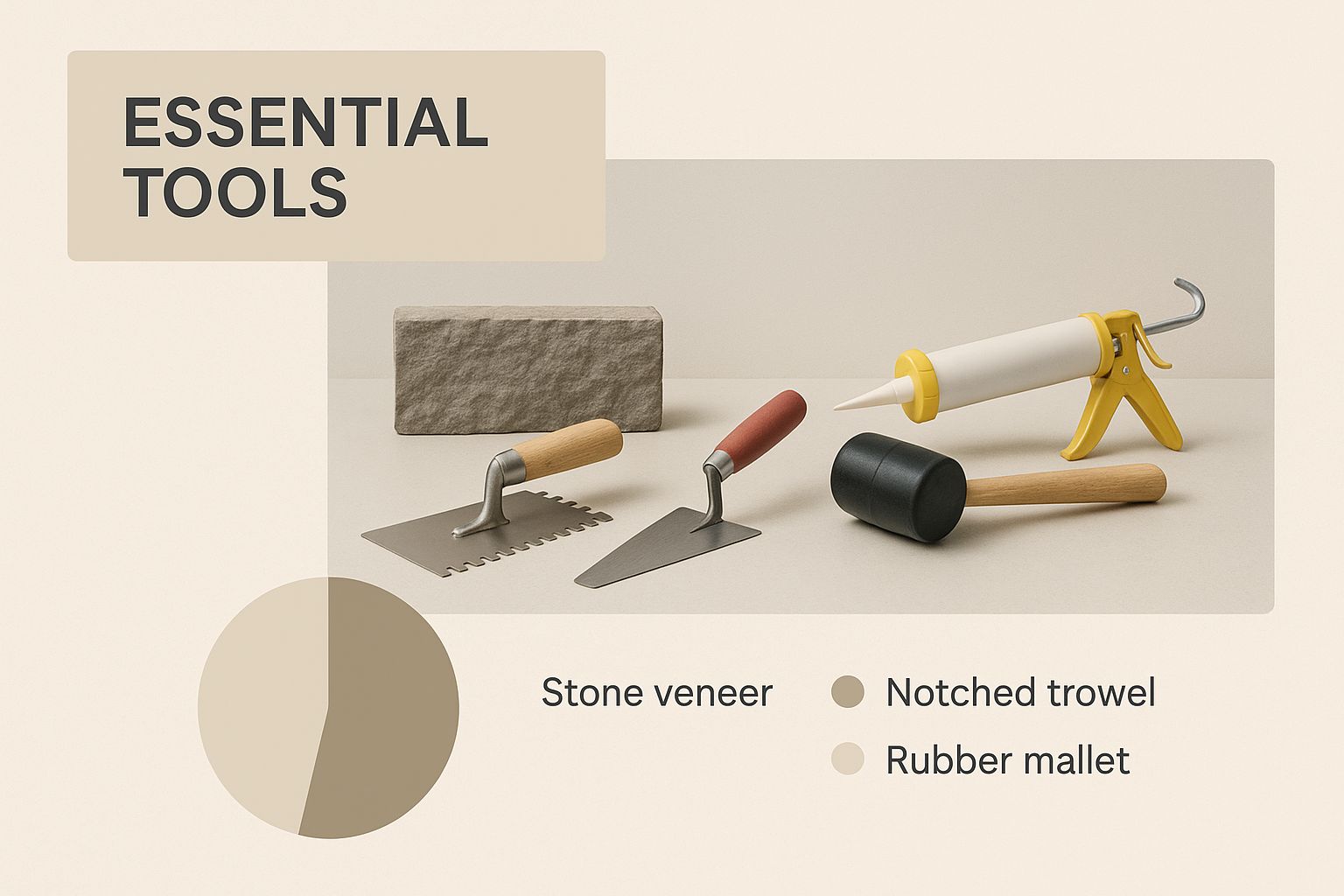

The infographic above showcases essential tools for a thin stone veneer installation. Having the right tools at hand streamlines the process and minimizes delays. Appropriate tools are as crucial as quality materials for achieving professional results.

Cost Comparison: Thin Stone Veneer vs. Traditional Stone

To help you visualize the financial differences between thin stone veneer and traditional stone, we've compiled the following table:

Cost Comparison: Thin Stone Veneer vs Traditional Stone

A detailed breakdown comparing material costs, installation fees, and total project expenses between thin stone veneer and traditional stone options in Australia

| Installation Type | Material Cost per m² | Labour Cost per m² | Total Cost Range | Installation Time |

|---|---|---|---|---|

| Thin Stone Veneer | $50 – $150 | $100 – $200 | $150 – $350 | 2-4 days |

| Traditional Stone | $300 – $400 | $200 – $300 | $500 – $700 | 7-10 days |

This table highlights the significant cost advantages of thin stone veneer. The faster installation time also contributes to lower overall labor expenses.

Managing Your Budget

Several factors influence your project's final cost:

- Project size: Larger projects naturally require more materials and labor.

- Complexity: Intricate designs increase labor expenses.

- Location: Labor costs can vary significantly across Australia.

Smart Timing and Financing

Timing is key. Material and labor costs can fluctuate seasonally. You might find better deals during the off-season. Explore financing options to make your project more affordable. Many Australian lenders offer home improvement loans specifically designed for renovations. Veneer Stone offers further insights into the financial benefits of thin stone veneer.

By carefully considering these factors and planning proactively, you can make smart decisions and achieve a beautiful thin stone veneer installation without overspending.

Modern Installation Systems That Actually Work

Forget outdated installation methods. Thin stone veneer installation has advanced significantly. New systems offer superior performance and longevity, outperforming traditional techniques. This ensures your veneer project not only looks beautiful but also stands the test of time.

The Shift From Traditional Mortars

Traditional site-mixed mortars, once the industry standard, presented numerous problems. Inconsistent mixing ratios and curing times often resulted in poor adhesion, delamination, and water intrusion. This meant higher maintenance costs and a reduced lifespan for the veneer. Thankfully, advancements in adhesive technology have changed everything.

Advantages of Modern Adhesive Systems

Modern adhesive systems deliver a level of precision and reliability unheard of with traditional mortars. Formulated specifically for thin stone veneer, they offer exceptional bonding strength and weather resistance. Some adhesives are freeze-thaw stable, crucial for withstanding Australia's varied climate. Many are also water-resistant, protecting against moisture damage and unsightly efflorescence. Want to simplify your installation? Learn more: How to easily install stone veneer.

In recent years, thin stone veneer installation has become more efficient and dependable thanks to advanced installation systems. Traditional site-mixed mortars often resulted in inconsistent quality and performance, leading to problems like delamination and water intrusion. Companies like LATICRETE have developed specialized systems that deliver high-strength, freeze-thaw stable, and water-resistant installations. Explore this topic further.

Ensuring Quality and Longevity

Waterproofing and Drainage

Waterproofing is essential for the longevity of any thin stone veneer installation. Modern systems use advanced waterproofing membranes and drainage mats. This protection prevents water damage, including efflorescence, a white, powdery substance that can ruin the veneer's appearance. These integrated systems offer a complete solution, protecting your investment from moisture.

Professional Installation Techniques

Proper installation is critical, no matter which adhesive system you choose. Skilled installers understand substrate preparation, adhesive application, and veneer placement. They have the right tools and expertise to ensure a perfect finish and long-lasting durability, handling corners, curves, and transitions with ease. This professional touch guarantees a beautiful, enduring result for your thin stone veneer.

Your Complete Installation Roadmap For Australian Conditions

Having explored the materials and systems, let's shift our focus to the practical steps involved in successfully installing thin stone veneer in Australia. This roadmap is designed to guide you through the process, addressing the unique challenges presented by Australia's varied climates.

Substrate Preparation: The Foundation of Success

A long-lasting thin stone veneer installation starts with proper substrate preparation. This means ensuring the surface is clean, stable, and compatible with your chosen adhesive. For timber frames, two layers of Water Resistive Barrier (WRB) are essential, along with a weep screed for effective moisture management. While a WRB isn't always required for masonry, maintaining the recommended clearances is crucial. Want to delve deeper into your veneer options? Check out our article on thin stone veneer options.

Adhesive Selection: Matching Climate and Material

Choosing the right adhesive is paramount. Factor in your local climate—from Darwin's humidity to Tasmania's cold—and select a product designed to perform in those conditions. Freeze-thaw resistant adhesives are a must in colder regions, while high-strength, water-resistant options are ideal for humid environments. Make sure the adhesive is compatible with both your veneer and the substrate material.

Installation Process: Precision and Patience

The installation itself requires precision and patience. Think of it like tiling—proper spacing and alignment are essential. Begin by applying the adhesive to the prepared substrate, working in manageable sections. Carefully position each veneer piece, ensuring a strong bond and consistent spacing. Spacers will help maintain uniform joints, creating a professional finish and allowing for movement due to temperature changes. For timber frames, use corrosion-resistant fasteners of the appropriate length to secure the lath, ensuring the veneer's weight is transferred effectively to the frame. Need more guidance on installation techniques? Consult our guide on installation methods.

Safety First: Protecting Yourself and Your Project

Safety should be your top priority throughout the installation process. Always wear appropriate Personal Protective Equipment (PPE), including safety glasses, gloves, and dust masks, particularly when cutting or grinding stone. Adhere to the manufacturer's instructions for adhesive and sealant application, ensuring adequate ventilation. When working at heights, use appropriate scaffolding and safety harnesses. A safe installation is a successful one.

Working with Australian Weather Conditions

Australia's climate can throw curveballs. In hot, dry conditions, dampen the substrate and the back of the veneer pieces before applying adhesive to prevent it from drying too quickly. In colder conditions, ensure materials are stored at the recommended temperature and consider using heated enclosures for proper curing.

Knowing Your Limits: When to Call a Professional

While many aspects of thin stone veneer installation are DIY-friendly, some situations call for professional expertise. If your project involves complex curves, significant heights, or challenging substrate conditions, consulting a qualified installer is wise. They have the skills and experience to handle these complexities, ensuring a flawless and long-lasting result. This is especially important for larger projects and exterior cladding.

Remember, a successful thin stone veneer installation hinges on careful planning, meticulous execution, and a solid understanding of Australia's unique building and climate conditions. By following this roadmap, you can achieve a beautiful, durable finish that enhances the value and style of your home.

Solving Problems Before They Become Disasters

Even the most meticulously planned thin stone veneer installations can run into unexpected problems. The difference between a successful project and an expensive disaster often lies in knowing how to tackle these issues head-on. This section, drawing on insights from experienced Australian installers, addresses the most common problems and offers effective solutions.

Identifying Substrate Irregularities

A level, stable substrate is the cornerstone of any successful thin stone veneer installation. Substrate irregularities can result in uneven veneer application, weak adhesion, and ultimately, cracking. Before you even begin installation, inspect the substrate thoroughly for any imperfections.

This could include bumps, dips, or pre-existing cracks. For instance, older brick walls may have deteriorated mortar joints that need repair before veneer installation can even be considered. Addressing these issues upfront will save you headaches down the line.

Mastering Moisture Management

Moisture is a significant threat to the longevity of thin stone veneer. Effective moisture management is essential to prevent problems like efflorescence, staining, and even structural damage. This involves correctly installing a Water Resistive Barrier (WRB), proper weep screed placement, and ensuring adequate drainage.

Choosing a water-resistant adhesive is also crucial for long-term protection. This is especially important in Australia's varied climates, where humidity and rainfall can fluctuate dramatically. Don't let moisture compromise your investment; prioritize moisture management from the outset.

Handling Thermal Expansion

Temperature changes cause materials to expand and contract. This thermal expansion can put stress on the thin stone veneer, leading to cracking or debonding if not properly managed. Using expansion joints and flexible adhesives allows for this movement.

Ensuring proper spacing between veneer pieces is also key, as this allows for expansion and contraction without causing damage. Thinking about a DIY installation? Check out these resources for DIY installation tips.

Addressing Common Installation Problems

To help you navigate potential issues, we've compiled a table outlining common installation problems, their symptoms, preventative measures, solutions, and when you might need professional assistance. This table provides a quick reference guide for troubleshooting your thin stone veneer project.

Common Installation Problems and Solutions

A comprehensive guide to identifying, preventing, and resolving the most frequent thin stone veneer installation challenges encountered in Australian conditions

| Problem | Symptoms | Prevention Method | Solution | Professional Required |

|---|---|---|---|---|

| Uneven Substrate | Uneven veneer surface, poor adhesion | Thorough surface preparation, leveling | Grinding, patching, or shimming | Possibly |

| Moisture Damage | Efflorescence, staining, cracking | Proper WRB installation, weep screed, water-resistant adhesive | Sealant application, improved drainage | Potentially |

| Thermal Expansion Cracking | Cracks in veneer | Expansion joints, flexible adhesive | Replacing cracked pieces, adding expansion joints | Likely |

| Delamination | Veneer separating from substrate | Proper adhesive selection and application | Re-adhering veneer, replacing damaged pieces | Yes |

The table above highlights the importance of preventative measures. Addressing potential problems early on can often prevent the need for more complex and costly solutions later.

Troubleshooting and Seeking Professional Help

Minor issues, such as small chips or cracks, can often be fixed with epoxy or color-matched fillers. However, more significant problems like widespread delamination or cracking often necessitate professional help.

Don't hesitate to consult a qualified installer if you encounter challenges beyond your expertise. Their experience can save you both time and money in the long run. Knowing when to call in the professionals is a sign of a wise homeowner and ensures a quality finish for your thin stone veneer project.

Protecting Your Investment For Decades To Come

Your freshly installed thin stone veneer dramatically transforms your home's exterior, adding a touch of timeless elegance. But the true secret to preserving its beauty and maximizing its lifespan lies in proper maintenance. This means understanding the unique challenges posed by Australia's diverse climate – from the corrosive salty air of the coast to the harsh, dusty conditions of the outback – and adapting your maintenance strategy accordingly.

So, are you ready to protect your investment and ensure your home continues to impress for years to come?

Creating a Maintenance Schedule That Works

A well-structured maintenance schedule is essential. Regular inspections, cleaning, and sealing will shield your veneer from the elements and prevent minor issues from escalating into costly repairs. A practical starting point is a visual inspection every six months, ideally in spring and autumn. This proactive approach allows you to identify and address potential problems early on. Want to learn more? Check out this helpful resource: How to master sealing stone veneer.

Cleaning Techniques: Preserving Beauty and Integrity

Cleaning your thin stone veneer requires a delicate touch. Harsh chemicals and abrasive cleaning tools can damage the surface and compromise the bond between the veneer and the substrate. Instead, choose a low-pressure wash with a mild detergent specifically formulated for stone. For stubborn dirt or stains, a soft-bristled brush can be used to gently lift away debris without causing damage.

Inspection Routines: Catching Problems Early

During your inspections, be vigilant for telltale signs of cracking, chipping, efflorescence, or loose veneer pieces. Pay particular attention to areas exposed to the harshest weather conditions, such as around windows and doorways. Early detection of these issues allows for timely repairs, preventing further damage and preserving the integrity of your veneer. For instance, efflorescence, a white powdery residue, often indicates moisture intrusion and requires immediate attention.

Addressing Common Warning Signs

Knowing the difference between minor cosmetic imperfections and significant structural problems is crucial. Small chips or cracks can often be easily repaired with color-matched fillers or epoxies. However, widespread cracking, significant efflorescence, or loose veneer pieces warrant professional intervention. Attempting DIY repairs on these more complex issues can exacerbate the problem and potentially void your warranty. Knowing your limits and seeking expert help when necessary is a sign of a smart homeowner.

Warranty Considerations and Professional Maintenance

Carefully review your warranty for specific maintenance requirements. Some warranties mandate the use of certain cleaning products or sealants, and failing to adhere to these stipulations could void your coverage. Consider engaging professional maintenance services for larger installations or complex repairs. Professionals possess the expertise and specialized equipment to handle challenging situations and ensure the long-term health of your investment.

Long-Term Care: Cost-Effective Strategies

Long-term care involves regular sealing of your thin stone veneer. Sealing provides a protective barrier against moisture, UV damage, and stains, dramatically extending its lifespan. The frequency of sealing depends on the type of stone and the specific climate conditions. In Australia's demanding environment, sealing every two to three years is generally recommended.

By implementing a consistent maintenance plan and addressing the unique needs of your thin stone veneer in the Australian climate, you can protect your investment and enjoy its stunning appearance for decades to come.

Key Takeaways

Your thin stone veneer installation journey, from start to finish, hinges on several key decisions. This guide distills practical advice from Australian experiences, offering a roadmap to a successful project. We'll equip you with actionable strategies, realistic timelines, and clear benchmarks to measure your progress.

Planning and Preparation Are Essential

Before starting your installation, thorough planning and preparation are paramount. Accurately assess your project's scope, realistically evaluate your DIY skills, and choose materials suited to Australia's unique climate. Substrate preparation is crucial for a beautiful and durable installation. Ensure the surface is clean, level, and structurally sound enough to support the veneer’s weight. A solid foundation prevents costly repairs down the line.

Modern Adhesive Systems Outperform Traditional Mortars

Traditional site-mixed mortars are outdated. Modern adhesive systems, engineered for superior performance and longevity, are transforming thin stone veneer installations. These advanced adhesives offer enhanced bonding strength, crucial freeze-thaw stability, and robust water resistance – essential for withstanding Australia’s diverse climate. Choosing the right adhesive dramatically impacts your project's long-term durability.

Proper Installation Techniques Are Key

Meticulous installation is vital for a professional, long-lasting finish. Consistent spacing and alignment, using spacers to maintain uniform joints, are crucial for both aesthetics and accommodating thermal expansion. For timber frames, corrosion-resistant fasteners of the appropriate length are essential for secure attachment. These small details significantly impact the final result.

Problem-Solving: Proactive Prevention and Effective Solutions

Even with meticulous planning, challenges can arise. Identifying and addressing substrate irregularities, implementing effective moisture management strategies, and accounting for thermal expansion are vital for preventing common installation issues. Understanding these potential problems, and how to address them, saves you time and money.

Maintenance: Protect Your Investment

After installation, proper maintenance preserves your veneer’s beauty and extends its lifespan. Regular inspections, gentle cleaning with appropriate detergents, and periodic sealing shield the veneer from Australia's harsh climate. This protects against damage from UV rays, moisture, and staining. A well-maintained veneer enhances your home’s appearance and value for years to come.

Key Decisions for Long-Term Success

-

Material Selection: Choose materials suitable for your project’s location and specific environmental conditions. Coastal areas, for example, benefit from materials with high salt resistance.

-

Installation System: Opt for modern adhesive systems designed for superior performance and longevity. Consider freeze-thaw resistant options for colder climates and water-resistant formulas for humid areas.

-

Professional Consultation: For complex projects, exterior cladding, or if you’re unsure about any aspect of the installation process, seek expert advice. A qualified installer provides valuable insights and ensures a flawless, lasting result.

-

Maintenance Plan: Create a practical maintenance schedule that includes regular inspections, cleaning, and sealing. This proactive approach protects your investment and prevents small issues from becoming expensive repairs.

By focusing on these key takeaways, your thin stone veneer installation will be a resounding success, adding lasting beauty and value to your Australian home.

Ready to transform your home with the elegance of thin stone veneer? Explore the innovative products from Flomary Group, combining natural stone beauty with advanced, lightweight technology.