The Evolution of Thin Stone Veneer: Why Designers Love It

Thin stone veneer has become a go-to material for both interior and exterior design projects. It offers the classic appeal of natural stone but with significant advantages in installation, cost, and overall versatility. This has propelled thin stone veneer from a niche construction material to a designer favorite.

From Heavy Stone to Streamlined Veneer: A Design Shift

Traditionally, using natural stone in design presented challenges: heavy weight, complex installation, and high costs. This often limited its use to structurally sound projects with substantial budgets. Thin stone veneer, however, has changed the game. Using a thinner cut of real stone reduces the weight by as much as 70%, expanding its use across a wider range of projects. Designers can now achieve the look of natural stone in places previously impractical. Considering thin stone veneer for your next project? Remember to evaluate the costs and benefits, just like with any other home improvements.

Versatility and Creative Freedom: Expanding Design Possibilities

This reduced weight also unlocks more creative possibilities. Thin stone veneer can be applied to curved surfaces, intricate designs, and even lightweight substrates. Imagine a curved fireplace clad in rustic stacked stone, or a textured accent wall in a compact apartment. These applications were simply not feasible with traditional, full-thickness stone. The wide availability of stone types, colors, and textures further empowers designers to customize the look for any project.

Market Growth and Demand

The popularity of thin stone veneer is evident in the growth of the manufactured stone veneer market. This sector is projected to reach $4.66 billion by 2033, increasing from $3.28 billion in 2025. The Asia Pacific region, in particular, is anticipated to experience an 82.58% rise in market revenue between 2021 and 2025, with an estimated compound annual growth rate (CAGR) of approximately 5.2% through 2033. This growth is attributed to factors such as rising urbanization, the demand for budget-friendly building materials, and a growing interest in sustainable construction practices. Learn more about the global market for manufactured stone veneer.

Enhanced Durability and Longevity: A Lasting Investment

Modern thin stone veneer is also engineered for durability. It’s designed to resist moisture, UV rays, and general wear and tear, making it suitable for both indoor and outdoor use. This resilience ensures that thin stone veneer offers long-term beauty and value. The lighter weight also simplifies installation, which can reduce labor costs and project timelines.

Natural vs. Manufactured: Choosing Your Perfect Stone Match

Choosing between natural and manufactured thin stone veneer is more than just an aesthetic decision. It impacts your project's budget, timeline, and overall value. Both provide the attractive look of stone, but differ in their composition, installation, and performance. Understanding these key differences is essential for making the right choice for your project.

Natural Thin Stone Veneer: Unique Beauty and Character

Natural thin stone veneer comes directly from quarries, where real stone is cut and shaped into thinner pieces. This preserves the stone’s natural beauty, including its unique color variations, textures, and veining. For instance, no two pieces of natural slate are ever truly identical, resulting in a one-of-a-kind appearance. This natural variation is highly valued in design projects emphasizing authenticity and unique character. However, this also means finding matching pieces for future repairs or additions can be difficult.

Manufactured Thin Stone Veneer: Consistency and Control

Manufactured thin stone veneer offers a different advantage: consistency. These products are made from a mixture of cement, aggregates, and pigments, designed to replicate the look of natural stone. This controlled manufacturing process ensures uniform color, texture, and size across every piece. This makes manufactured stone veneer perfect for large projects or when a predictable result is essential. It's also often lighter than natural stone, making installation easier.

To help you compare the two options, we've created a table highlighting the key differences and similarities between natural and manufactured thin stone veneer.

To help you understand the key differences, we've compiled the following comparison:

Natural vs. Manufactured Thin Stone Veneer Comparison

|

Factor |

Natural Thin Stone Veneer |

Manufactured Thin Stone Veneer |

|---|---|---|

|

Appearance |

Unique, varied colors and textures |

Consistent color and texture |

|

Cost |

Typically more expensive |

Typically less expensive |

|

Weight |

Heavier |

Lighter |

|

Installation |

Can be more complex |

Easier and faster installation |

|

Durability |

Highly durable |

Durable, but can be susceptible to fading or chipping |

|

Maintenance |

May require sealing |

Generally lower maintenance |

|

Availability |

Can be limited depending on the type of stone |

Readily available in a variety of styles |

|

Repair/Matching |

Difficult to find matching pieces |

Easy to find matching pieces |

This table summarizes the key differences between natural and manufactured thin stone veneer, allowing for a quick comparison across important factors. Choosing the right material depends on balancing your design vision with practical considerations.

Weighing the Pros and Cons: A Visual Approach

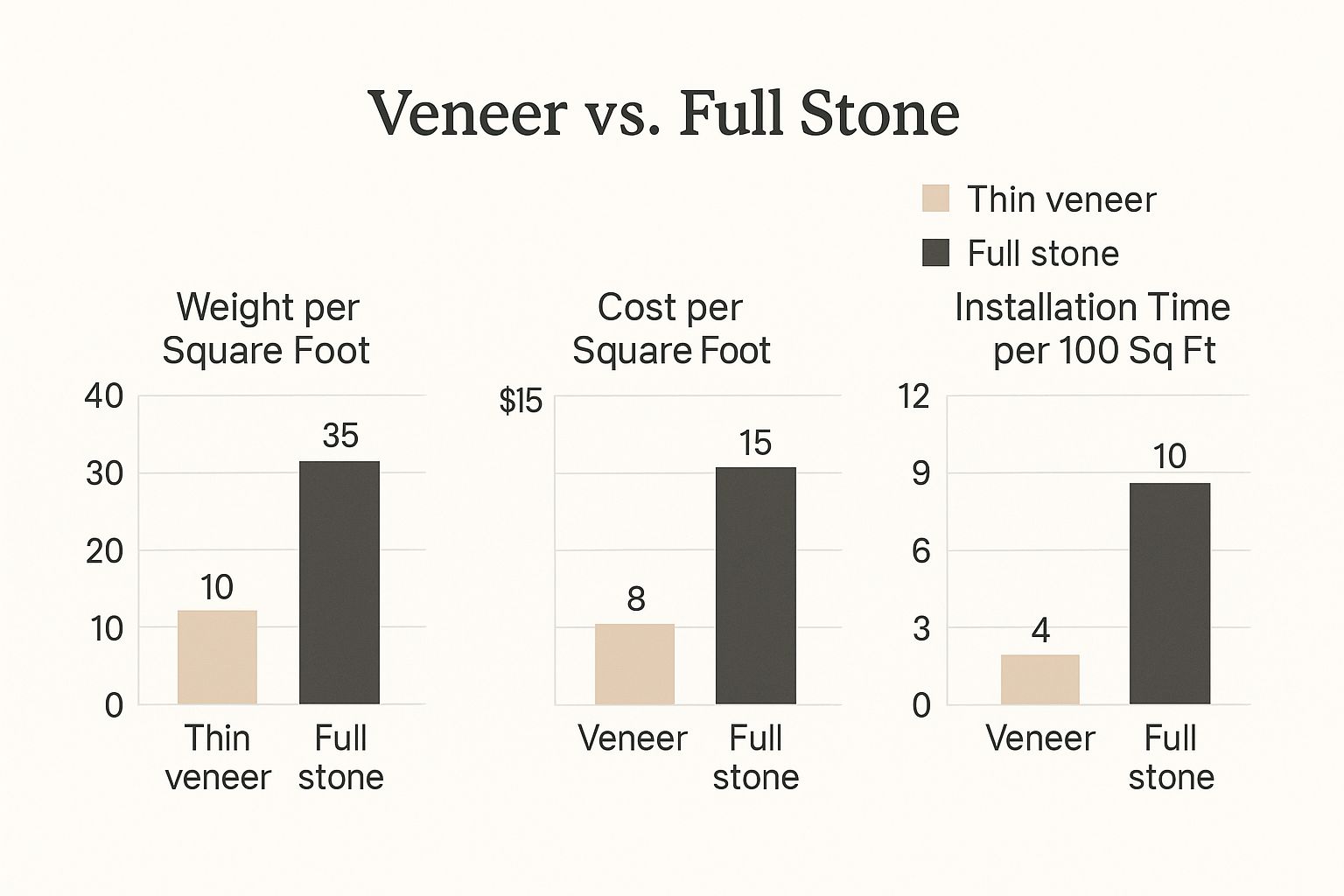

The infographic below visually represents the differences in weight, cost, and installation time between thin stone veneer and full stone:

Thin stone veneer offers considerable advantages over full stone. While thin veneer weighs just 10 lbs per square foot, full stone weighs 35 lbs. This makes thin veneer easier to handle, requires less structural support, and installs faster, taking only 4 hours to install 100 sq ft compared to 10 hours for full stone. The cost difference is also significant, with thin veneer at $8 per square foot versus $15 for full stone. These practical advantages make thin stone veneer a compelling choice.

Making the Right Choice for Your Project

Choosing between natural and manufactured thin stone veneer depends on your project's specific needs and priorities. Balance your desired aesthetic with your budget and installation requirements. If a unique, high-end look is paramount and budget is less of a concern, natural stone veneer might be the ideal choice. If consistency, affordability, and ease of installation are top priorities, manufactured stone veneer is a practical and effective solution. By carefully considering these factors, you can choose the material that best brings your design vision to life.

Ultra-Thin Revolution: Stone Veneer’s Game-Changing Innovation

Thin stone veneer has always been a strong alternative to heavy, traditional stonework. However, ultra-thin stone veneer takes this concept to a whole new level. These remarkably thin profiles, some as thin as 1/8 inch, are changing how architects and designers approach both residential and commercial projects.

Redefining Possibilities: Where Traditional Stone Falls Short

Ultra-thin stone veneer opens up design possibilities previously unavailable with traditional stone. Its light weight makes it suitable for areas where traditional stone is simply too heavy. Think elevator interiors, renovations with weight restrictions, and even intricate ceiling designs. This is a significant change from the past, where structural limitations often prevented the use of natural stone, particularly in renovations or projects with challenging weight limitations.

The Science Behind the Slim: Cutting and Reinforcement Techniques

Creating ultra-thin stone veneer involves specialized cutting and reinforcement. Manufacturers use advanced methods to slice natural stone into incredibly thin sheets while preserving its strength. This often involves backing the stone with a reinforcing material for added stability and flexibility. This process allows ultra-thin veneer to retain the beauty of natural stone while boasting impressive strength. These advancements are continuously evolving, leading to even thinner and more durable products.

Market Growth and Projections

Ultra-thin stone veneer has become a rapidly growing segment of the construction materials market. Currently valued at about $1.2 billion in 2024, the market is projected to reach $2.5 billion by 2033, demonstrating a CAGR of approximately 8.9%. You can find more detailed statistics here.

A Modern Aesthetic: Blending Stone with Contemporary Materials

Beyond its practical advantages, ultra-thin stone veneer offers a distinct contemporary aesthetic. Its sleek profile complements modern materials like glass and metal, creating attractive contrasts and visual interest. Designers are increasingly incorporating ultra-thin veneer to bring a touch of natural elegance to minimalist spaces. This seamless blend of natural textures with industrial elements is highly valued in modern design.

The Future of Facades: Lightweight, Sustainable, and Stylish

Ultra-thin stone veneer represents a significant advancement in building materials. Its reduced weight translates to lower shipping costs and a smaller environmental footprint. Simpler installation also contributes to faster project completion times. The combination of sustainability, practicality, and aesthetic appeal positions ultra-thin stone veneer as a top material choice for architects and designers. As technology continues to develop, we can anticipate even more innovative uses for this game-changing material.

Mastering Thin Stone Veneer Installation: Pro Techniques

Selecting the right thin stone veneer is just the first step. The installation process itself is crucial for ensuring the project's longevity and aesthetic appeal. Just like finding DIY skylight installation tips for other home improvements, understanding the nuances of thin stone veneer installation is essential for a successful outcome. This section explores the critical steps to achieve professional-looking results.

Substrate Preparation: The Foundation of Success

The first, and often most overlooked, step is preparing the substrate. This is the underlying surface onto which the veneer will be applied. Whether it's concrete, brick, or wood, the substrate must be clean, stable, and free of any debris. Imperfections in the substrate will telegraph through the veneer, impacting the final appearance and potentially weakening the installation.

Moisture management is another critical factor, especially for exterior projects. Excess moisture can lead to problems down the road, compromising the integrity of the veneer. A well-prepared substrate is like a solid foundation for a house – essential for supporting everything built upon it.

Adhering the Veneer: Techniques and Tools

Once the substrate is properly prepared, the next step is applying the adhesive mortar. This specialized mortar is specifically formulated for bonding thin stone veneer. An even application is key to ensuring full contact between the veneer and the substrate.

Many professionals use notched trowels to create grooves in the mortar. This technique, similar to tiling, increases the bonding surface area and creates a stronger hold. Precision and an understanding of the specific mortar's properties are essential for proper application.

Securing the Veneer: Reinforcements and Techniques

Depending on the project, additional reinforcement may be needed. For larger installations or areas exposed to harsh weather, using metal lath or a scratch coat can provide extra support. These reinforcements help distribute the weight of the veneer, preventing cracking or detachment.

Cement backer board is another option that provides a stable substrate and enhances moisture management, further protecting the veneer installation. These additional steps provide long-term stability and prevent future issues.

Finishing Touches: Achieving a Professional Look

The final step involves applying grout and sealer. Grouting fills the spaces between the veneer pieces, enhancing the overall aesthetic and providing a finished look. Choosing a grout that complements the stone's color and texture is important for visual appeal.

Sealing the veneer is essential for protection against moisture, staining, and other environmental factors. This final step preserves the veneer’s beauty and ensures its longevity. Just like the previous steps, using the right tools and techniques is key to a professional finish.

Before diving into the final steps, let's review some essential installation requirements. The following table details the tools, materials, and preparation steps necessary for different installation scenarios:

Thin Stone Veneer Installation Requirements

|

Installation Surface |

Required Materials |

Preparation Steps |

Special Considerations |

|---|---|---|---|

|

Concrete |

Adhesive mortar, notched trowel, grout, sealer, metal lath (optional) |

Clean and level the surface, ensure proper moisture content |

May require a scratch coat for added stability |

|

Brick |

Adhesive mortar, notched trowel, grout, sealer, metal lath (optional) |

Clean and remove any loose mortar, ensure proper moisture content |

Consider the brick’s porosity and potential for efflorescence |

|

Wood |

Adhesive mortar, notched trowel, grout, sealer, cement backer board, moisture barrier |

Install cement backer board and moisture barrier, ensure proper ventilation |

Wood substrates require careful moisture management |

This table summarizes the key elements required for successful installation on various surfaces. Considering these factors beforehand ensures a smoother, more efficient process.

Troubleshooting and Expert Tips

Even with meticulous planning, challenges can arise. Lippage, where adjacent veneer pieces are uneven, can occur due to inconsistent mortar application or variations in veneer thickness. Efflorescence, a white powdery residue, can appear due to moisture migration.

Understanding these common issues and their solutions is crucial for a successful project. Sometimes, knowing when to seek professional guidance is as important as knowing how to handle certain tasks yourself. This knowledge can save time and resources in the long run.

Design Inspiration: Thin Stone Veneer Projects

Thin stone veneer offers incredible design flexibility. It's no longer limited to cladding entire walls. Instead, designers are using it to create focal points and add unique character to both interior and exterior spaces. Let's explore the innovative ways designers are using this versatile material.

Breaking the Rules: Unconventional Applications and Patterns

Designers are venturing beyond traditional applications, incorporating thin stone veneer in unexpected places. Imagine a kitchen backsplash crafted from intricately patterned slate tiles. Or perhaps a bathroom accent wall featuring a mosaic of polished pebbles. These unconventional uses add visual interest and a touch of luxury.

Experimentation with patterns is also on the rise. Moving beyond the standard stacked or linear arrangements, designers are creating herringbone designs, geometric patterns, and even artistic murals using different colors and textures of thin stone veneer. This allows for personalized designs that reflect individual style.

Material Fusion: Integrating Stone with Contrasting Elements

The combination of contrasting materials can create stunning visual effects. Consider a sleek, modern fireplace framed by the rough texture of stacked stone veneer. Or a contemporary kitchen island clad in thin stone veneer paired with a smooth quartz waterfall countertop.

This integration of contrasting elements—such as the warmth of wood against the cool touch of stone—adds depth and sophistication to any space. The contrast highlights the unique qualities of each material, creating a harmonious balance.

Enhancing Spaces: Visual Expansion and Added Value

Thin stone veneer can significantly impact a space's perceived size and value. In smaller rooms, lighter-colored stone veneer can create an illusion of spaciousness. A small bathroom, for example, can feel larger with a light, textured limestone accent wall.

Incorporating thin stone veneer, even in small amounts, can increase a property's perceived value. A striking stone veneer accent wall in an entryway can create a memorable first impression and add a sense of luxury.

Case Studies: Award-Winning Projects and Designer Secrets

Analyzing award-winning projects reveals how different stone profiles achieve specific aesthetic outcomes. Large-format, polished porcelain tiles that mimic natural stone create a sleek, modern look. Smaller, more rustic pieces of natural stone veneer achieve a timeless, traditional charm.

Lighting plays a crucial role in showcasing the texture and depth of stone. Strategically placed uplighting can emphasize the three-dimensional quality of a textured stone veneer wall, creating dramatic shadows and highlights. Designers also use consistent stone elements to create seamless transitions between indoor and outdoor spaces, extending the design aesthetic throughout the property. This continuity creates a unified and harmonious flow.

Creating Seamless Indoor-Outdoor Transitions

One of the most effective uses of thin stone veneer is to create a visual connection between indoor and outdoor living areas. Using the same stone veneer on an interior feature wall and an exterior patio, for example, can blur the lines between inside and out.

This design technique creates a sense of continuity, expanding the perceived living space. By carefully selecting the right stone and considering the lighting, homeowners can achieve truly impressive results with thin stone veneer.

Thin Stone Veneer ROI: Maximizing Your Investment

Thin stone veneer offers more than just an attractive facade; it's a savvy investment that can significantly increase your property's value. This section explores how thin stone veneer projects can offer a strong return on investment (ROI) across various markets and price points.

Understanding the Financial Benefits of Thin Stone Veneer

Thin stone veneer has consistently proven to be a valuable addition to homes, often recouping a significant portion of the initial cost upon resale. This is partly due to the enhanced curb appeal and the perception of luxury that stone veneer adds to a property. For example, a 2024 Cost vs. Value report indicated a remarkable 153% ROI for manufactured stone veneer. This makes it an attractive option for homeowners looking to boost their property's market value.

Strategic Applications for Maximum ROI

While completely cladding a home's exterior in stone can make a dramatic statement, strategic applications of thin stone veneer can often offer a higher ROI.

-

Accent walls

-

Fireplace surrounds

-

Entryway features

These smaller projects offer impactful visual enhancements without the expense of a full-scale renovation. This balance between cost and impact maximizes the return on your investment.

Material Selection and Long-Term Savings

The type of thin stone veneer you choose significantly impacts both the initial cost and long-term maintenance expenses. While some premium materials might have a higher upfront cost, they can offer long-term savings because of their durability and reduced maintenance needs. For example, high-quality natural stone veneer, although initially more expensive, may require less maintenance and replacement compared to some manufactured options, resulting in overall savings down the line.

Market Growth and Future Value

The projected growth of the U.S. stone veneer market underscores the increasing value of this material. Valued at $675.7 million in 2023, the market is expected to reach nearly $1 billion by 2032. This growth, fueled by demand in both new construction and renovation, highlights the growing popularity of stone veneer for both interior and exterior applications. Find more detailed statistics here.

Budgeting and Cost Considerations

Project costs for thin stone veneer vary based on factors like the type of stone, the project scope, and regional labor rates. A full exterior renovation will naturally have a higher price tag than a smaller accent wall. Labor costs can also fluctuate significantly depending on your location.

Creating a realistic budget requires carefully considering these factors. Getting multiple quotes from contractors and comparing material prices are essential for accurate cost estimation. This helps avoid unexpected expenses and keeps your project aligned with your financial goals.

Buyer Appeal and Competitive Advantage

In a competitive real estate market, thin stone veneer can give your property a distinct advantage. It elevates a home's perceived value and adds a touch of elegance that appeals to buyers. This can lead to quicker sales and potentially higher offers, maximizing the return on your thin stone veneer investment.

Elevate your designs and maximize your investment with Flomary Group's premium selection of ultra-thin stone veneer and flexible tiles. Explore our extensive catalog and discover how we can help you bring your vision to life. Visit Flomary Group today!