Understanding Australian Stone Veneer Flashing Requirements

Protecting your stone veneer investment in Australia's varied climate demands a keen understanding of flashing. Just like a raincoat shields you from the rain, flashing acts as a critical barrier against water damage for your home. Whether battling Queensland's tropical humidity or Tasmania's cooler temperatures, proper flashing is essential to avoid costly repairs and structural problems. This involves understanding both the general principles of moisture management and the specific guidelines set by the National Construction Code (NCC).

Why Proper Flashing is Critical

Imagine water seeping behind your stunning stone facade, causing mould, rot, and potentially compromising the entire structure. This isn't a superficial issue; it's a costly and potentially hazardous problem. Proper flashing installation is the first and most important defense. It blocks water penetration, safeguarding the underlying structure and preserving the veneer's integrity. For instance, neglecting proper flashing around windows and doors can lead to water entering the wall cavity, resulting in expensive repairs and unhealthy mould growth. This makes flashing a cornerstone of every successful stone veneer project.

NCC Compliance and Australian Standards

The NCC strictly regulates stone veneer flashing details in Australian construction. This ensures durability and effective moisture control in masonry veneer walls. According to Part 3.3.5 of the NCC 2019 Volume Two Amendment 1, continuous damp-proof courses and flashing are mandatory around the base of walls on concrete slabs, below suspended floors, and where the roof meets the wall. Learn more about the NCC requirements for masonry veneer: NCC Masonry Veneer Requirements. These standards guarantee a project that isn't just visually appealing, but also structurally sound and compliant with building codes. Understanding these regulations is crucial for both builders and homeowners.

Key Flashing Locations

Certain areas demand extra attention to flashing details:

-

Window and Door Openings: These are especially susceptible to water intrusion and require meticulous flashing installation.

-

Roof-Wall Intersections: Correctly installed flashing here prevents water from flowing down the wall and into the building.

-

Parapet Walls: These exposed walls require robust flashing to shield them from the elements.

-

Foundation Perimeter: A comprehensive damp-proof course and flashing system at the base of the wall prevents rising damp and protects the structure's foundation.

By grasping the importance of flashing and adhering to Australian standards, you can ensure the longevity of your stone veneer project. It remains a beautiful, durable feature of your property, offering long-term cost savings and peace of mind knowing your investment is secure.

Navigating NCC Compliance and Building Standards

The National Construction Code (NCC) is your blueprint for durable and compliant stone veneer flashing installations. It’s the foundation for creating structures built to withstand the test of time, not just a checklist to be ticked off. Understanding the specific requirements within Part 3.3.5 is paramount to achieving this.

Mandatory Flashing Locations

The NCC clearly defines where flashing is mandatory, ensuring consistent protection against water damage throughout Australia. This proactive approach safeguards your projects against potential issues.

These mandatory locations are strategically identified to mitigate the most common vulnerabilities. For instance, continuous damp-proof barriers are required at the base of walls on concrete slabs and below suspended floors.

This crucial step prevents rising damp and protects the structural integrity of the foundation. Additionally, flashing at roof-wall intersections diverts water away from the wall cavity, preventing costly repairs down the line. Perimeter walls also require meticulous flashing details for effective water runoff management.

Flexibility and Exceptions

While the NCC provides strict guidelines, it also recognizes the need for adaptability. Under specific circumstances, some flexibility is allowed. For example, with adequate eaves protection, certain flashing requirements might not apply.

However, thoroughly understanding these exceptions is crucial. Don't just assume – verify! Consulting with a compliance expert is a wise investment. They can provide tailored guidance for your project, ensuring compliance while optimizing costs.

Understanding Key Factors Affecting Flashing Design

Several key factors within the NCC will influence your flashing design choices. Maximum veneer wall heights dictate specific flashing details to effectively manage wind loads and water penetration.

Wind load classifications, especially in coastal regions, play a critical role. These classifications determine the required type and strength of flashing to withstand harsh weather conditions. Properly addressing wind loads is essential for long-term structural integrity.

Furthermore, wall tie spacing requirements impact how the flashing integrates with the overall wall assembly. Adhering to these requirements ensures a weather-resistant and structurally sound installation, minimizing future maintenance needs.

Interpreting the NCC for Practical Application

The NCC isn't about memorizing regulations; it's about practical application. Consider a double-storey home project in a high-wind zone. The NCC's stipulations on maximum wall heights and wind loads will directly influence your flashing selections.

You might need heavier-gauge flashing and additional fixings to meet the code requirements. This proactive approach ensures a robust and resilient structure.

By understanding and applying the stone veneer flashing details outlined in the NCC, you're building projects that are both compliant and enduring. This protects your clients and solidifies your reputation for quality craftsmanship. The NCC is your indispensable guide to successful, long-lasting stone veneer installations.

Choosing The Right Materials For Australian Conditions

Australia's harsh climate, with its intense UV exposure, fluctuating temperatures, and moisture challenges, demands careful consideration when selecting flashing materials for stone veneer. Choosing the right flashing is crucial for the longevity of your veneer. This means understanding material properties, corrosion resistance, and how materials react to thermal movement. Learn more in our article about types of stone veneer.

Material Selection For Longevity

From traditional lead-coated copper to modern flexible membrane systems, every flashing material has advantages and disadvantages. Lead-coated copper, for example, offers exceptional durability but carries a higher price tag. Flexible membranes provide easier installation, especially around complex shapes, but may have a shorter lifespan. Choosing the correct material is essential for long-term performance.

Material thickness also plays a significant role. Thicker materials typically offer increased protection and durability. However, they can be harder to work with and may necessitate specialized tools for installation. Finding the optimal balance between thickness and workability is vital.

To help visualize the various options available, we've compiled a table summarizing key differences between various flashing materials:

To help you choose the right flashing material, we've put together a comparison of some popular options. This table highlights the key factors you should consider for your project.

Stone Veneer Flashing Material Comparison: Comparison of different flashing materials showing durability, cost, installation complexity, and suitability for Australian conditions.

| Material Type | Durability (Years) | Cost Rating | Climate Suitability | Installation Complexity |

|---|---|---|---|---|

| Lead-Coated Copper | 75+ | High | Excellent | Moderate |

| Stainless Steel | 50+ | Medium | Good | Moderate |

| Aluminum | 20-30 | Low | Fair | Easy |

| Flexible Membrane (e.g., PVC) | 15-20 | Low | Fair | Easy |

This table clearly illustrates the trade-offs between cost, durability, and installation complexity. While lead-coated copper offers superior longevity, budget-conscious projects may benefit from considering stainless steel or flexible membranes, while acknowledging their potentially reduced lifespan.

Corrosion Resistance and Compatibility

Galvanic corrosion, the electrochemical deterioration resulting from the contact of dissimilar metals in the presence of moisture, poses a serious threat to flashing integrity. It can lead to premature failure and damage the surrounding stone. Carefully evaluate the compatibility of all materials used, including the stone type, mortar system, and sealants. For instance, pairing stainless steel fasteners with copper flashing can trigger a galvanic reaction.

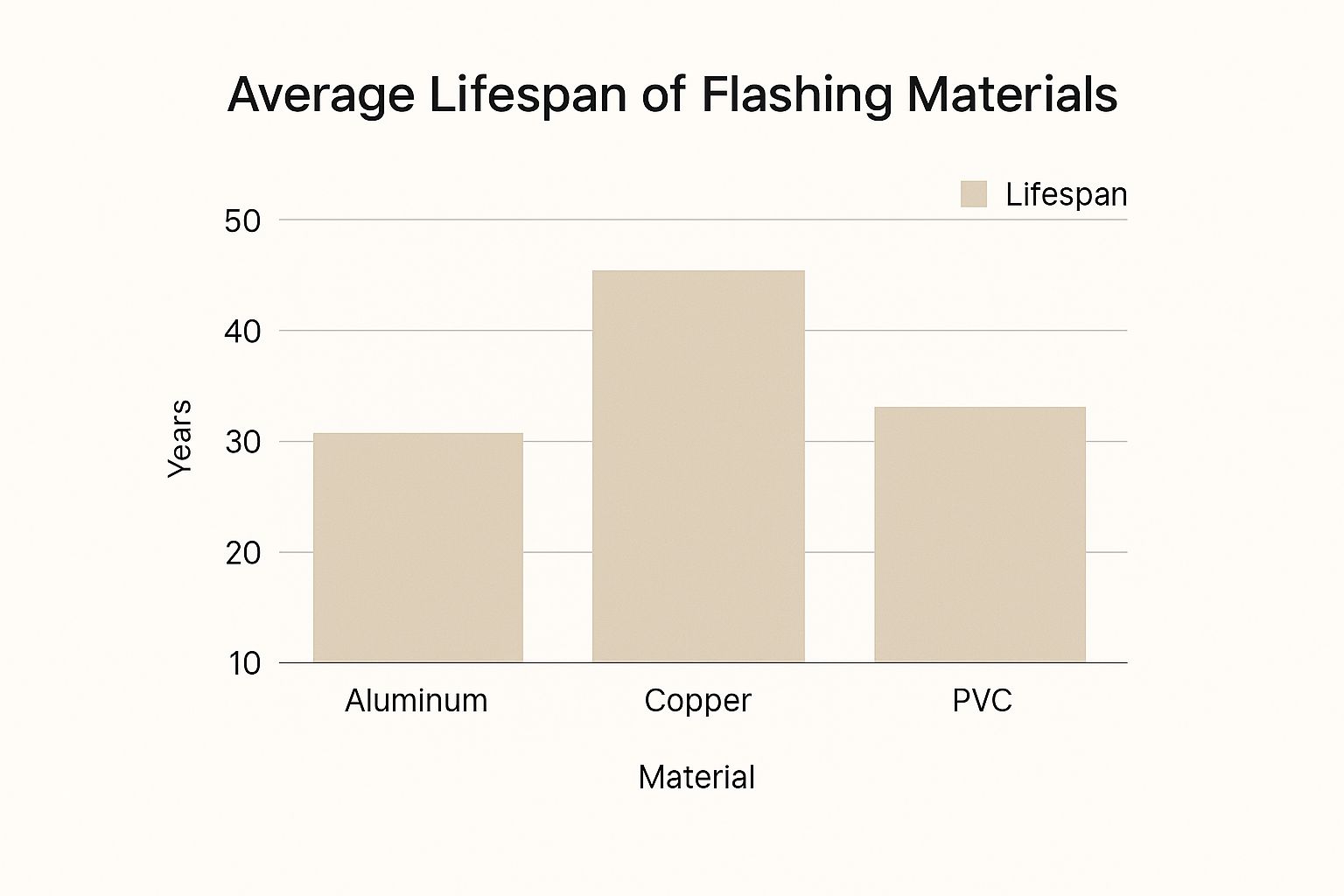

This infographic visually compares the average lifespan of three common flashing materials: aluminum, copper, and PVC. The data clearly shows copper's significant longevity advantage over aluminum and, especially, PVC. Choosing a highly corrosion-resistant material with a long lifespan minimizes future maintenance and replacement expenses – a smart long-term investment.

Thermal Movement Considerations

Australia's wide temperature swings cause materials to expand and contract, stressing the flashing. Opt for materials engineered to handle this thermal movement without cracking or compromising their seal. Flexible membrane systems often excel in this area, accommodating expansion and contraction more effectively than rigid materials. Ignoring these thermal dynamics can lead to leaks and expensive repairs down the line. Selecting the right flashing is crucial for a successful project. By carefully considering the factors discussed, you can ensure the long-term performance and beauty of your stone veneer project.

Mastering Installation At Critical Connection Points

This is where the true test of quality lies: ensuring your stone veneer flashing details are perfect at every critical junction. We'll guide you through proven techniques for even the most challenging installations, from common failure points like window and door openings to the intricacies of roof-wall intersections. This is crucial knowledge for any builder working with stone veneer in Australia.

Watertight Corners And Thermal Movement Joints

Skilled builders know that watertight corner details are the foundation of any successful stone veneer installation. This requires precise cutting and folding of the flashing material to create an impenetrable barrier against water penetration. Equally important in Australia's varied climate is the management of thermal movement joints.

Temperature fluctuations cause expansion and contraction of materials, potentially jeopardizing the flashing's integrity. By incorporating flexible sealant and expansion joints, you can accommodate this movement while preserving a watertight seal. Learn more: How to master waterproofing stone veneer.

Drainage Slopes And Complex Architectural Features

Ensuring proper drainage slopes, even in seemingly insignificant areas, is paramount. Even a slight slope allows water to flow away efficiently, preventing pooling and subsequent damage. Standard flashing techniques, however, often prove inadequate for complex architectural features.

Bay windows, balconies, and parapet walls, for example, demand more advanced approaches. Consider custom-fabricated flashing pieces to achieve a truly weatherproof seal in these intricate areas.

Lapping, Securing, and Integrating With Cavity Drainage

Proper lapping of joints is essential to prevent water ingress. Overlapping the flashing material like shingles ensures water flows over, not behind, the joints. Securely fastening flashings without damaging vapour barriers is also critical.

Using specialized fasteners and sealant prevents punctures in the vapour barrier, preserving its crucial role in moisture control. Finally, integrating the flashing system with cavity drainage is vital. This typically involves weep holes and drainage channels, allowing any trapped moisture to escape.

Troubleshooting And Quality Control

Even seasoned builders face complex installation challenges. This is why troubleshooting is so essential. Recognizing warning signs like staining or efflorescence allows for early intervention, preventing more serious problems down the line.

Implementing quality control throughout the installation process also catches errors before they become costly callbacks. This includes meticulous inspections at every stage to verify the accuracy and security of all flashing details. By mastering these techniques, you can guarantee the longevity and aesthetic appeal of your stone veneer projects, offering lasting protection against the elements.

Australian Stone Veneer Market Trends and Material Selection

The Australian stone veneer market is experiencing a surge in popularity, significantly impacting the choices you make for flashing on your projects. One prominent trend is the increasing demand for locally sourced materials. This preference has a ripple effect, influencing everything from flashing design and installation to its long-term performance. For best results, be sure to check out the most recent window and door sealing tips.

The Rise of Australian Stone

Australian stone veneers, crafted from native quarried stone, possess distinct textures and a rich array of colors. These qualities imbue projects with an undeniable authenticity and visual appeal, making them highly sought after by discerning homeowners. This trend reflects a broader shift towards sustainable, locally produced building materials. The rise of stone veneer cladding in Australia is largely due to its aesthetic charm and the growing use of locally sourced materials. For instance, in 2024, brick veneer comprised approximately 29.91% of external wall materials in Australian homes, followed by fiber cement cladding at 12.42%. More comprehensive statistics can be found here. This burgeoning demand influences not only the aesthetic aspects of a building but also the essential technical components of construction, particularly flashing details.

Impact on Flashing Design and Installation

The inherent properties of Australian stone varieties directly influence stone veneer flashing details. The stone's porosity, for example, impacts how it reacts to moisture, requiring careful consideration of flashing materials and proper installation techniques. The weight and density of the stone also play a role, impacting the structural support and anchoring needed for the flashing system. A robust and well-designed flashing system is crucial for preventing water damage and ensuring the longevity of the stone veneer.

Artisanal Stone Veneer and Modern Flashing Systems

The increasing popularity of artisanal stone veneer work adds another layer of complexity to flashing installation. Skilled craftsmanship is essential to seamlessly integrate modern flashing systems with the intricate designs often found in bespoke stonework. This meticulous approach preserves both the aesthetic vision and the structural integrity of the project. This level of detail demands precision, especially around vulnerable connection points where moisture can penetrate.

Material Selection and Performance Across Climate Zones

Australia's varied climate zones present unique challenges for building materials. Coastal regions, exposed to salt air, require corrosion-resistant flashing. Inland areas, subject to extreme temperature fluctuations, need flashing systems that can withstand expansion and contraction without compromising their effectiveness. Understanding these regional differences and selecting appropriate materials is paramount for long-term performance and client satisfaction. Consider not only the initial cost, but also the lifetime cost of the flashing system, factoring in maintenance and potential replacements. By understanding these market trends and material considerations, builders can ensure their projects are both beautiful and durable, meeting the demands of Australia's diverse climate.

Identifying Problems Before They Become Disasters

Protecting your investment in stone veneer starts with proactive prevention. Addressing flashing issues early can save significant time and money, preventing small problems from escalating into costly disasters. This section explores common flashing failures, teaches you how to spot them, and empowers you with effective solutions.

Common Flashing Failures and Their Causes

Understanding the root causes of flashing failure is the first step towards effective prevention. Inadequate lapping, where flashing overlaps are too short, is a frequent culprit. This allows water to easily penetrate behind the veneer, leading to moisture damage within the wall cavity.

Poor drainage slopes are another common issue. Water needs a clear, unimpeded path to run off. Insufficient slopes allow water to pool, eventually seeping into the wall. Incompatible materials, such as using dissimilar metals, can cause galvanic corrosion, gradually degrading the flashing over time. Finally, installation errors, like incorrect sealant application or poorly secured flashings, create vulnerabilities that invite water damage.

Recognizing the Early Warning Signs

Early detection is crucial for minimizing damage and preserving the beauty of your stone veneer. Efflorescence, a telltale white, powdery deposit on the stone surface, can signal moisture lurking behind the veneer. Staining or discoloration also suggests water penetration. More obvious signs, such as structural movement like cracks or bulging in the veneer, and cavity saturation, where the wall cavity feels damp, demand immediate attention.

Diagnostic Techniques and Repair Strategies

Several diagnostic techniques can pinpoint flashing issues. A moisture meter accurately measures moisture levels within the wall cavity, providing quantifiable data to assess the extent of the problem. Thorough visual inspections, meticulously checking flashing overlaps and sealant integrity, can also reveal problem areas. Repair strategies depend on the severity and cause of the damage. Resealing or patching may suffice for minor issues. More extensive damage might necessitate replacing sections of flashing or even the veneer itself.

Cost-Effective Approaches and Maintenance Strategies

Fortunately, cost-effective solutions exist for addressing flashing problems. Retrofitting flashing in existing buildings, by adding flashing to vulnerable areas, offers a practical approach to enhancing protection. Upgrading older systems to meet current performance standards significantly improves water resistance. Regular maintenance is paramount for extending the life of your flashing. Annual inspections, checking for signs of damage or deterioration, are essential. Cleaning weep holes and drainage channels prevents blockages that contribute to water buildup.

Communicating With Clients

Clear communication with clients about the importance of flashing is essential for successful project outcomes. Explain the potential consequences of flashing failure, emphasizing the significant costs associated with neglecting this critical component. Highlight the benefits of preventative maintenance, presenting it as a cost-effective investment that protects their property. Provide clients with a detailed maintenance schedule, empowering them to take proactive steps in preserving their stone veneer. By educating clients about the crucial role of stone veneer flashing details, you equip them to protect their investment and avoid costly repairs in the future.

To assist you in identifying and addressing flashing issues, consult the following table:

Stone Veneer Flashing Failure Analysis:

| Problem Type | Primary Cause | Visual Symptoms | Repair Method | Prevention Strategy |

|---|---|---|---|---|

| Water Ingress at Window Head | Inadequate flashing lapping | Staining above window frame | Extend flashing overlap, reseal | Ensure sufficient overlap during installation |

| Corrosion at Wall Base | Incompatible flashing and fasteners | Rust stains, deteriorated flashing | Replace flashing with compatible materials | Use compatible materials from the outset |

| Cavity Saturation | Blocked weep holes | Efflorescence, damp wall cavity | Clear weep holes, improve drainage | Regular cleaning and inspection of weep holes |

This table summarizes common flashing problems, their causes, visual symptoms, effective repair methods, and proactive prevention strategies. By utilizing this resource, you can stay ahead of potential issues and ensure the longevity of your stone veneer installations.

Professional Installation Best Practices That Actually Work

Excellence in stone veneer flashing hinges on proven practices. These practices guarantee long-term performance and compliance with Australian standards. This means a focus on quality control, detailed inspections, and thorough documentation. These are the hallmarks of professional installations. Want to learn more about manufactured stone? Check out this helpful resource: How to master manufactured stone installation.

Timing and Coordination

Proper timing is critical for success. Flashing installation must be strategically sequenced within the overall construction timeline. Effective coordination with other trades is essential. This ensures flashing is installed at the right time and integrates seamlessly with other building components.

For example, flashing at window and door openings must be coordinated with the window and door installation. This maintains a watertight seal, prevents conflicts, and ensures a smooth, efficient workflow.

Weather Protection, Tool Selection, and Safety

Protecting your work from the elements is non-negotiable. Weather protection during installation prevents moisture damage to the flashing. Selecting the right tools is equally important. Appropriate tools ensure clean, precise cuts and secure fastenings. Just as a surgeon needs the right instruments, a professional installer needs specialized tools for optimal results.

Safety should always be the top priority. Stone veneer work involves potential hazards, including working at heights and handling heavy materials. Using appropriate safety equipment and following safe work practices is crucial. This protects both workers and the quality of the installation. This includes providing workers with proper harnesses, scaffolding, and eye protection. Effective planning and scope management are also vital to avoid costly mistakes. Understanding strategies for managing project scope creep can be invaluable.

Testing, Documentation, and Quality Assurance

Testing the installation's integrity is crucial for a weathertight seal. Water testing, for example, simulates rainfall to identify any leaks. Maintaining detailed installation records is essential. This includes material specifications, installation dates, and quality control checks. These records provide valuable documentation for warranty purposes and demonstrate professionalism.

Providing clients with clear and comprehensive documentation builds trust and supports warranty requirements. This package should include installation details, maintenance recommendations, and contact information.

Checklists and Quality Assurance Procedures

Using checklists and quality assurance procedures ensures consistent, high-quality results. These tools provide a systematic approach to every stage of the installation. This covers everything from material inspection to final testing. Using these tools minimizes callbacks and builds a reputation for reliability. In the competitive construction market, this is a major advantage. These practices demonstrate a commitment to excellence that sets professionals apart.

Ready to elevate your projects with high-quality, sustainable stone veneer? Explore the innovative product range from Flomary Group. Get inspiration, expert advice, and a free quote today. Transform your designs with the timeless beauty and modern performance of Flomary stone.